Polyethylene terephthalate glycol or PETG filament is one of many filament materials used in fused deposition modeling (FDM 3D printing). It offers better material properties as compared to Polylactic Acid PLA filament and Acrylonitrile Butadiene Styrene ABS filament. This material is slightly flexible, durable, cheap, and lightweight, making it a great choice for 3D printing.

PETG is chemically stable, water resistant, and offers greater product shelf life in outdoor applications but at the same time, it’s harder to print as compared to PLA and ABS. This article is about understanding PETG material for 3D printing applications. This includes materials properties, different types of filament available, printer hardware requirements, and tips to avoid PETG-related 3D printing problems.

Material Properties of PETG Filament 3D Printed Part

PETG is manufactured by making “Glycol” modifications in PET, a common material known for its use in plastic water bottle manufacturing. PETG has all properties of PET but as PET is modified to PETG for 3D printing, the recycling properties change from recyclable PET to nonrecyclable PETG.

Parts 3D printed using PETG filament offer great temperature resistance (thermal stability). It can withstand temperatures of up to 85-degree centigrade. Above this temperature printed parts start to soften and lose their dimensional and shape accuracy.

It mostly depends on the filament brand and how users 3D print the material but PETG can offer a material strength of 13 to 30 Mega Pascal (MPa). This means our PETG 3D printed part can resist external pressure of up to 30 MPa. It’s sufficient for most domestic applications and some small industrial applications where plastic and 3D printing is the only choice.

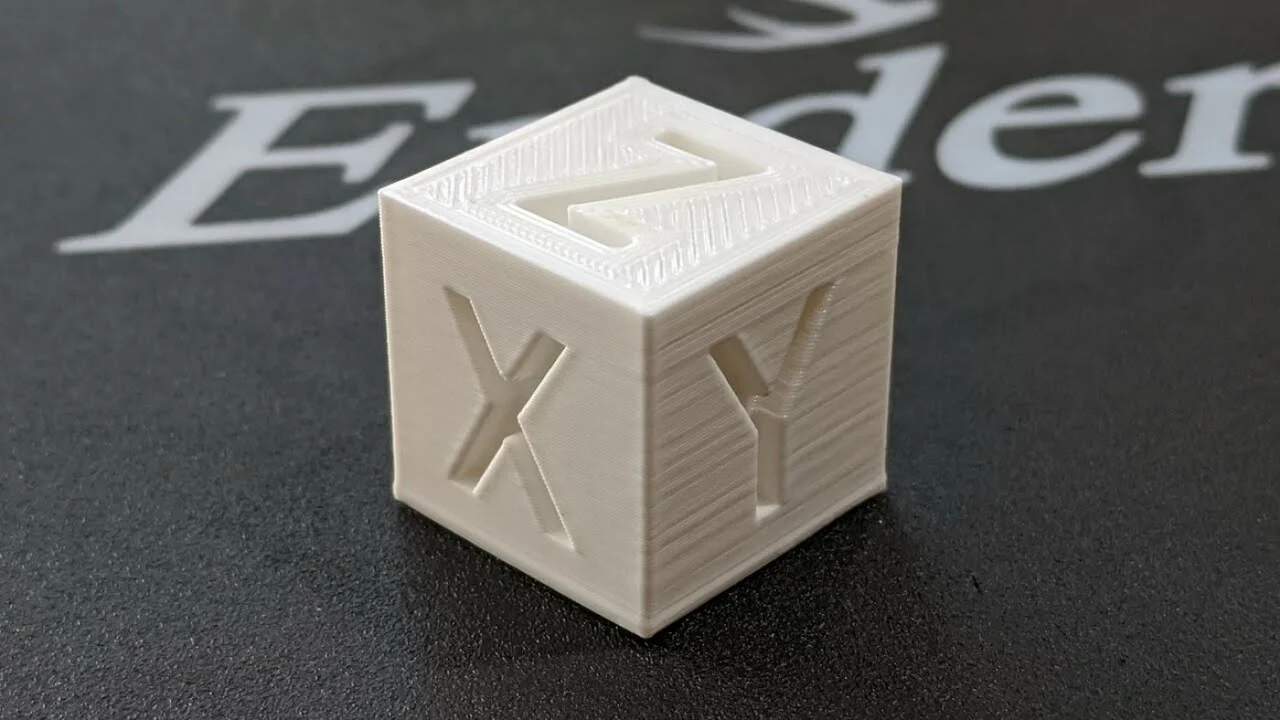

PETG delivers quite lightweight printed parts as it has a low material density of just 1.2 grams per cubic centimeter. This means a complete solid X Y Z calibration cube of 1 cubic centimeter volume when printed with PETG will only wait for 1.2 grams.

Advantages of PETG Filament

- PETG filament due to its material chemical and physical properties always produces a glossy and smooth surface on the final 3D print

- Unlike ABS filament, PETG does not produce any bad odor while printing so can be used in confined spaces with no special ventilation required

- PETG material is sticky and gives excellent adhesion with 3D printer bed

- Due to its slow cooling process, PETG gives minimal warping

Disadvantages Of PETG Filament

- The sticky nature of PETG makes it adhere better to bed and also makes it adhere to the nozzle thus causing nozzle clogging

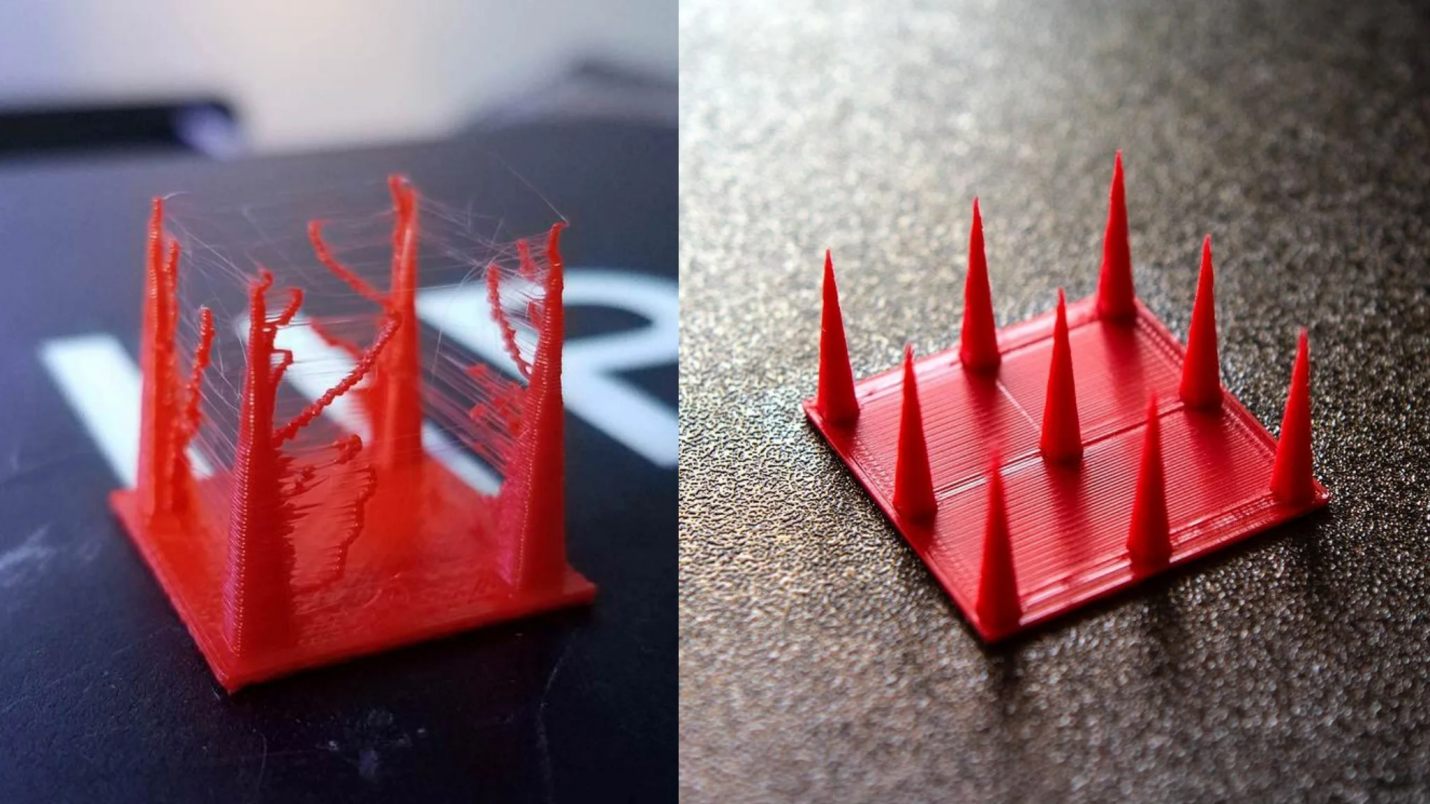

- This property of PETG also produces stringing problems in 3D printing

- This stringing creates thin hair-like strings coming out of the final 3D print

- PETG filament material has poor bridging characteristics that limit its application

Application of PETG Filament

Due to its chemical and water resistant abilities and little flexibility, PETG filament is mostly used in all those outdoor applications where any type of fluid is involved or the product needs little flexibility. These application includes

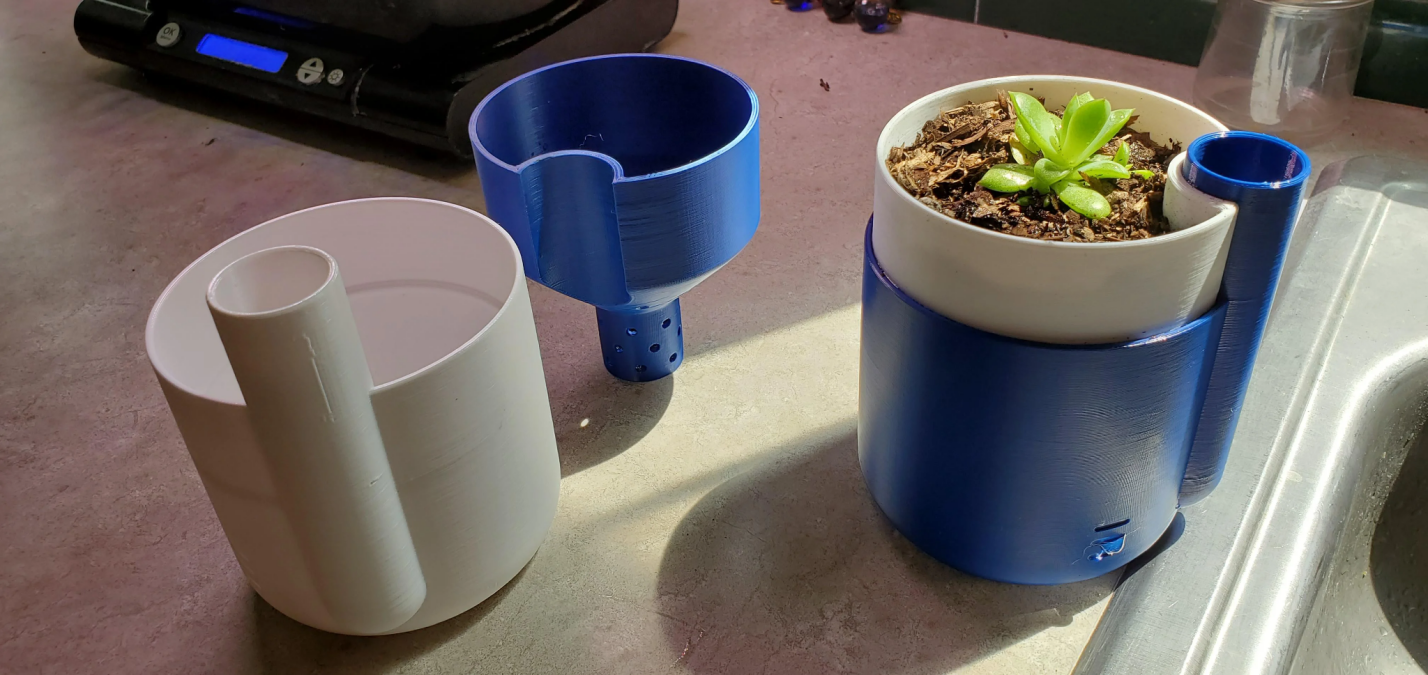

- Decoration piece

- Waterproof products

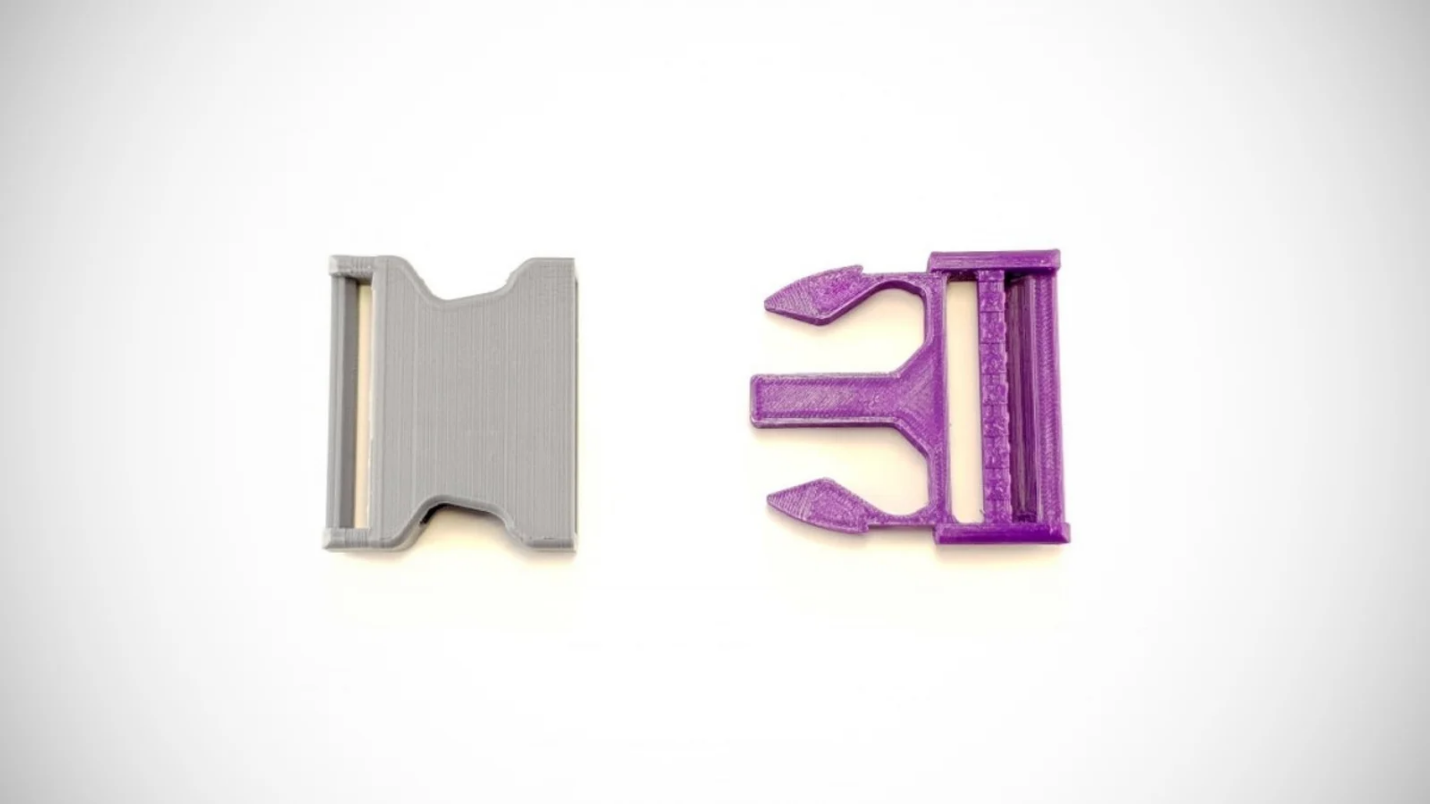

- Snap-fit products

- planter pots

Some of the most famous products 3D printed using PETG includes

- Self Watering planters

- Water bottles

- Snap-fit parts

Types of PETG Filaments Available

In the PETG filament domain, there are three basic types of filaments available for consumer end users. These includes

- Standard PETG Filament

- PETG Pro Filament

- PETG CF filament

Standard PETG filament is the most commonly used and widely available filament in the PETG material domain. It offers all advantages of PETG material with an addition of multiple color options like green, brown, black, clear filament, and many more. Filament has a standard diameter of 1.75 mm and is available in a standard 1 Kg spool.

PETG Pro filament is an advanced and improved form of standard PETG filament. Manufactured to deliver extra strength, toughness, zero warping, and high moisture resistance this filament is to print high-strength outdoor application. Pro filament is also available in multiple colors of your choice.

PETG CF filament is a composite form of standard PETG filament with carbon fiber reinforcement. This material was engineered to deliver high strength, impact resistance, toughness, wear resistance, zero warping, and high moisture resistance. CF filament is only available in b;ack color and is used for small industrial application.

Printer Hardware Requirements for PETG Filament

PETG filament is one of the hard-to-print 3D printing materials. Due to its glossy nature, it sticks a lot on the nozzle and print bed. To print PETG with perfection, there are some specific 3D printer hardware requirements, like extruder temperature, bed temperature, and cooling fan speed.

Extruder or printer nozzle temperature is the first and most important requirement for printing this filament. A nozzle temperature of a minimum of 230 and a maximum of 260 degrees centigrade is required for PETG.

The printer bed temperature is crucial for proper material adhesion during 3D printing. A bed temperature of a maximum of 90 degrees centigrade is required for printing PETG without warping. Printing PETG is not possible without a heated bed, so it’s a requirement, not an option.

Part cooling using a part cooling fan is compulsory while printing with PETG filament. Due to the high melting temperature of PETG and high bed temperature, the part can take time to cool without fan cooling. This can cause a decrease in the dimensional accuracy of parts. Quick cooling of parts with 100% fan speed ensures dimensional accuracy and high print quality.

Build surface of the 3D printer is also very important when printing PETG. A heated surface is one thing but surface quality/smoothness and adhesion are another. A heated bed with a glass surface is highly recommended as it makes things very smooth for PETG filament 3D printing.

Tips for PETG Filament 3D Printing

- The temperature required for PETG depends a lot on the brand and manufacturer. Starting with a temperature tower test will help you to identify the best temperature setting for your filament. In the temperature tower test, a tower of different segments is printed with each segment being printed at a different temperature.

- If your printer heated bed temperature is below the recommended temperature of PETG. Then using a glue stick or painter’s tape is recommended for proper bed adhesion.

- Keep the part cooling fan off when printing the first layer of the part, this helps avoid warping of the part, especially when printing large-size parts. Start the part cooling fan after the first or second layer is completed.

- A raft is an extra layer of material printed before the printing part. When printing PETG raft helps to maintain a glossy texture and gives a clean surface to the PETG filament.

- Stringing is a common issue with PETG filament and a retraction setting is the only solution. Start with calibration of the retraction setting of your printer before printing products.

- PETG is hygroscopic, meaning it absorbs moisture from the environment. So keeping your PETG in a dry place or a filament enclosure is recommended.

Conclusion on PETG Filament 3D Printing

PETG filament is a better option than PLA and ABS. As it offers chemical stability and high resistance against water and moisture. It also has higher strength, flexibility, and product shelf life when compared to PLA and ABS. With its glossy surface texture and slow cooling after printing, it can print parts of very high quality. Due to its sticking nature, PETG filament is a little harder to print as compared to PLA and ABS.

Follow TechStrange for more!